- Overview

- Course outline

- Entry

- Career path

- How to apply

Course Overview

Developed to meet the skills gap that exists across a range of industries as a result of digital transformation, this programme equips participants with a key blend of skills related to technology, operational excellence and complex problem-solving skills in order to participate in a successful and future-facing organisation.

This programme will provide learners with the digital skills needed to successfully operate within advanced manufacturing and support services. Learners will gain an understanding of organisational strategy, forecasting and supply chain management. The programme will also introduce a range of lean tools such as 5S, SMED, Kanban, Kaizen, error proofing and level loading. In addition, learners gain an understanding of the fundamentals of six sigma, data integrity, statistics, FMEA, systems analysis, quality tools and control strategies. Learners will also develop skills to communicate effectively in a digital environment.

This in-demand Certificate is designed and developed with your career advancement in mind, helping people gain employment in some of Ireland’s leading companies.

This programme develops graduates’ capabilities to keep pace with rapidly occurring changes in the nature of operators’ work in advanced manufacturing settings. The programme will help learners to maintain the currency of their CVs and contribute value in a changing workplace. The programme will provide learners with a foundational knowledge of some of the core elements of process digitisation.

Designed and delivered by highly experienced academics and industry professionals, our lecturers know the skills and knowledge that companies are looking for. Our unique part-time, online delivery allows learners to log on live or catch up by watching the recorded sessions which can also be used for revision. Extensive coaching and mentoring workshops will be provided with a specific focus on individual assessment and improvement.

Accreditation: QQI Level 6 Minor Award in Operational Excellence for Process Digitisation

Next Intake: January 2026. Now accepting applications.

Course Outline

The course duration is 11 months. Lectures will be delivered two evenings per week online and two Saturday’s per month, one of which will be delivered in-person. (ECTS: 60 Credits)

Module 1: Fundamentals of Maths and Statistics

Provides learners with the basic knowledge, skills and competence they will require to solve practical mathematical problems within a digitized industrial setting. Maths is additionally a fundamental tool in computer programming. This module will therefore provide learners with a solid base of skills using mathematical tools that will be used in subsequent advanced modules e.g., Industrial statistics and Programming modules within this programme.

Module 2: Transversal Skills

Provides learners with the skills to recognise the changing environmental climate and identify and demonstrate a range of newly required transversal skills and competencies to act in such an environment. Learners will also develop their ability to prepare an appropriate CV, successfully complete an interview and present themselves in the best possible manner are key elements of the module. An additional element of the module is to assist learners to develop their network which will aid their entry into the industry.

Module 3: Operations Management & Supply Chain Management

Provides learners with a basic understanding of operations management and supply chain management in manufacturing and service organisations. The key functions of operations management involve organisational strategy, product design, forecasting, inventory management, quality control, scheduling, supply chain management and facilities management. Key characteristics of common supply chain strategies and criteria for their selection are presented, as well as an introduction to key performance metrics for supply chain management. Learners will develop their competence to contribute to the functions that design, plan, direct and improve all the activities that transform resources into goods or services in manufacturing and services companies.

Module 4: Operational Excellence – Lean thinking

Provides an overview of the fundamentals of organisational success, the concept of value, quality and waste in the business environment. Learners develop their knowledge of the concept and principles of lean thinking, value stream mapping and process mapping. The module introduces the learner to the range of lean tools utilised in waste elimination, such as 5S; SMED; Kanban; Kaizen; error-proofing and level loading. The module also discussed the importance and impact of culture on the lean transformation journey.

Module 5: Operational Excellence – Six Sigma

Introduces the learner to the fundamentals of six-sigma as a method to reduce variation and understand root cause. Understanding the importance and validity of quality data is critical to any improvement strategy, hence the module also covers fundamentals of data integrity, measurement systems analysis, statistics, quality tools, cause and effect, FMEA, solution development and control strategies. The module also introduces the learner to the creative problem-solving tool TRIZ and the importance of blue-sky thinking and transdisciplinarity. Finally, the module provides an overview of a typical Corrective Action Preventative Action (CAPA) process, based on the DMAIC methodology, introducing the learners to risk identification and risk assessment.

Module 6: Emerging Trends in Operations Management

Provides a basic understanding of some trends that accelerate the smart manufacturing future – product manufacturing and service convergence; redefined processes; hybrid human-machine processes; manufacturing ecosystems and manufacturing culture. Learners will develop an awareness of the impacts of the implementation of Industry 4.0, the increased importance of being sustainable and the rise of supply chain technology or blockchain.

Module 7: Fundamentals of Project Management

Aims to give students a basic knowledge of project management techniques used to identify the roles involved (in a team) and the processes used when managing an industrial project from the conceptual stage to full completion. It also aims to enable the student to understand the main aspects of project management methodologies together with key elements of control, risk and financial evaluation.

Module 8: Digital Communication & Technical Reporting

Introduce learners to the discipline of technical communication. Acquiring technical writing skills is essential in workplace contexts where process digitisation is occurring, as it enables personnel to accurately communicate thoughts, ideas, information, and messages in writing; and create documents such as letters, directions, specifications, manuals, reports, presentations, graphs, flow charts, etc. Preparation of visuals to supplement the text, workplace communication, descriptions of mechanisms, explanations of processes, and writing reports are the major topics included.

Entry Requirements

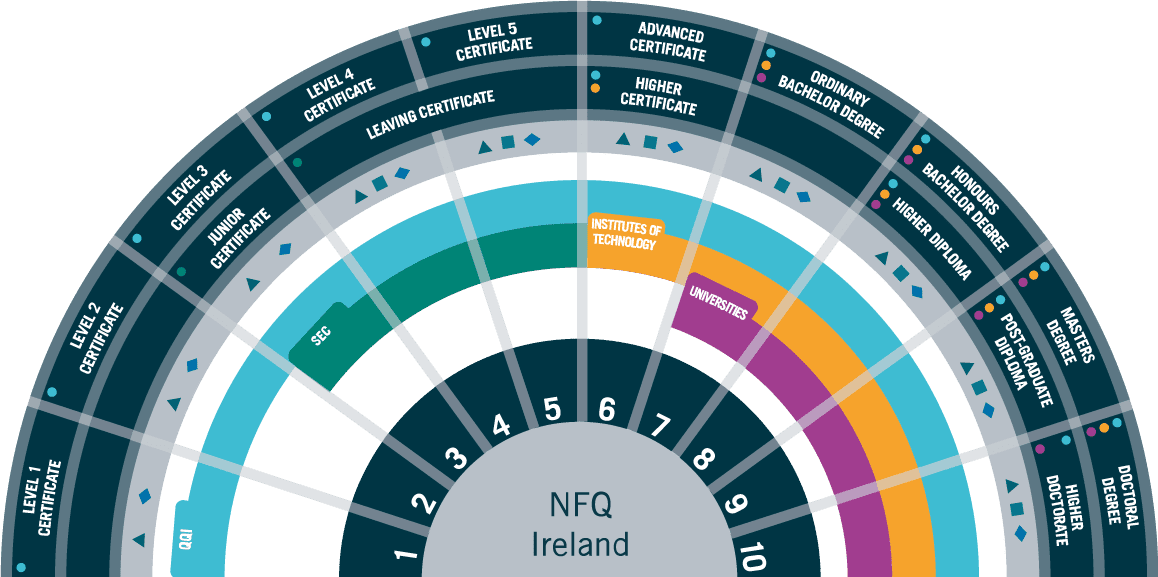

This course is suitable for those with a minimum qualification at NFQ Level 5 or Leaving Certificate with a minimum of a H7/O6 in five leaving cert subjects, one of which must be mathematics. Learners who do not meet the minimum mathematics criteria can avail of free access to a self-paced mathematics bridging programme and examination to facilitate entry.

The English language entry requirements for the programme are a B2+ level or equivalent on the Common European Framework of Reference for Languages (CEFR). Candidates with English language levels below CEFR B2+ must first reach this minimum standard before enrolling on the programme.

Mature students with relevant industrial experience are also eligible.

Career Options

This course was designed with a large range of industries in mind. Graduates can expect employment across a number of sectors in roles such as:

- Manufacturing Operator

- Manufacturing Technician

- Product Builder

- Process Technician

- Logistics/Warehouse Operator

- Business Improvement Specialist

- Supply Chain Support

Progression

Learners who have completed the Certificate in Operational Excellence for Digitisation can progress to the Certificate in Information Technology for Digitisation.

Learners who have completed the Certificate in Information Technology for Digitisation can progress to the Certificate in Operational Excellence for Digitisation.

Learners who have completed both the Certificate for Operational Excellence for Digitisation and the Certification in Information Technology for Digitisation can progress to a BSc in Process Digitisation.

Learners who have completed the Higher Certificate in Science in Process Digitisation may progress to any third level college providing NFQ Level 7 programmes in relevant domains and for which learners can provide evidence that they satisfy the stated entry requirements. For example, the Innopharma – Griffith College NFQ Level 7 BA in Pharmaceutical Business.

Apply Now

Our admissions team are on hand to assist you with your application and answer any questions you may have on the course.

Students who wish to apply to this course should follow the following application process.

Step 1: Enquire through the form at the top right of this page

Step 2: A member of our team will be in contact through phone or email

Step 3: If you are deemed to be eligible for the course, you will be sent an application form by email. You MUST fill in this application form and attach all necessary *documents (CV, ID, Transcripts, etc.)

Step 4: On submission of the completed application form and all documentation, your application will be sent to the associated department for final approval. You will receive an e-mail confirming your place on the programme. (Note: This process can take up to one week particularly during busy admission periods.)

*We accept scanned documents in a pdf format. Pictures of documents are not accepted.

**For those who are applying for Springboard funding, you will be directed to fill out an additional application form on the Springboard website, this is to confirm your eligibility to receive funding

Please note at any time if you have any questions please do not hesitate to contact us by email on admissions@innopharmalabs.com or call us (01) 485 334

Why up-skill for the STEM process manufacturing sectors in Ireland?

- Over 130,000 employed within these industries

- Over 40,000 new jobs predicted

- Over €62 billion in exports

- 9 of top 10 world’s biopharma companies in Ireland

- 8 of the top 10 worlds medtech companies in Ireland

- Over 8,000 new jobs predicted by 2020

Testimonials

The lectures all come from the industry so they know what the Pharmaceutical companies are looking for

Laura McCarthy, ERP Automation Admin at Pfizer Certificate in Pharmaceutical & Medical Device Operations Graduate

Our Blog

Blog

February 9, 2026

The Open Research Revolution: Digital Transformation and the Future of Evidence-Based Learning

Author: Colm O’Connor, College Librarian & Research Specialist, Innopharma Education In today’s rapidly evolving...

Blog

February 3, 2026

Digital Transformation: Cultivate the Talent Rather Than Buy the Platform

Author Finbarr Sheehy Digital transformation is often sold as a technology story: choose the right platform, implement it well and...

Blog

December 12, 2025

The Life Sciences Workforce Is Changing — Are You Ready?

AI is no longer a futuristic idea hovering on the horizon — it’s already woven into the daily reality of pharma, biopharma, an...