- Overview

- Course outline

- Entry

- Career path

- How to apply

Course Overview

This in-demand certificate is designed and developed to help students kick-start their life science careers, helping students gain employment in some of Ireland’s leading Pharma & Medtech companies such as Pfizer, MSD, Stryker, Mylan, Roche and many more.

This programme consists of a blend of science, quality, business and personal development modules, suitable for those who are seeking an entry-level role in the sector or want to gain industry-specific knowledge for career development. You will gain expertise in manufacturing technology, science, quality regulations, GMP and cleanroom operations.

Modules Include:

- Pharmaceutical Science

- Manufacturing Process Technology

- Quality Assurance & GMP

- Quality Control & GMP

- Process Improvement

- Medical Device Operations

- Utilities & Facilities Management

- Professional Development for STEM

- Learning to Learn

Developed and taught by industry and academic lecturers, this course is delivered through blended learning, 2 evenings per week online and up to 2 Saturdays per month in class.

Accreditation: QQI Level 6 Minor Award in Pharmaceutical and Medical Device Operations

Collaborating University: Technical University Dublin – Tallaght Campus

Next Intake: January 2026. Now accepting applications.

Continue to the Course Outline section for module information.

Course Outline

The course duration is 9 months. Lectures will be delivered 2 evenings per week online. Students will also be required to attend 2 Saturdays a month on campus. (ECTS: 65 Credits)

Module 1: Pharmaceutical Science

Pharmaceutical dosage forms; drug product formulation and their chemical function; unit operations in pharmaceutical manufacturing processes; prepare granulates, formulate tablets, and analyse final formulations; types of packaging, closure systems and tamper-evident seals and labels used for a product.

Module 2: Facilities and Utilities Management

Understand the fundaments of Facilities / Utilities Management, Heating Ventilation and Air Conditioning (HVAC), Review Pharmaceutical Water Systems, Aseptic Processing, Cleanroom Technology, Clean In Place (CIP) technology and validation of CIP and Understand Isolation technologies, Sterilisation Methods and Sterility testing

Module 3: Quality Control and GMP

The agencies which regulate healthcare manufacturing; management of regulatory documentation; the principles of Validation; the QC testing pathway; QC specifications of ingredients, components and products.

Module 4: Quality Assurance & GMP

Regulatory requirements for pharmaceutical manufacturing; documented procedures, Standard operating procedures, Batch manufacturing records; the role of audits, corrective actions and change control; the role and function of Quality Control and Quality Assurance; the role of the employee in delivering products; Interpretation and use of quality specifications.

Module 5: Medical Device Operations

Medical interventions and treatments provided to patients; operation of a medical device manufacturing facility; Good Manufacturing Practices and Quality Systems in medical device manufacturing; manufacturing processes and standards used during the processing of medical device products.

Module 6: Manufacturing Process Technology

The steps normally used in a typical drug development process from discovery to market; the organisation of a pharmaceutical plant and the functions of each department; the synthesis and purification of chemicals on a large scale; the equipment used in a bulk pharmaceutical plant and its operation; Waste treatment plant; record data during the manufacturing process.

Module 7: Preparation for Work for STEM

The importance of networking in today’s society; develop a personal carer plan; Write an appropriate CV that provides an outline of academic and employment experience; techniques and behaviours required to successfully succeed a job interview.

Module 8: Process Improvement

Implementation of Lean and 6 Sigma process improvement tools such as; Value stream Mapping, 5S, OEE. Carrying our quality Investigation (Deviations) including use of Root Cause Analysis tools and implementing CAPA. Completion of lean 6 Sigma project.

Module 9: Learning to Learn

Personal Strengths and weaknesses as a learner, set specific learning goals and create a personal learning plan; Study effectively as an independent learner and work collaboratively as a member of a team; Manage time efficiently with regard to planning and organising learning tasks; Use critical thinking and analytical skills to solve a variety of problems; Write a research-based report and make an effective presentation; the importance of academic integrity and identify ways of avoiding plagiarism in academic work through appropriate referencing.

Entry Requirements

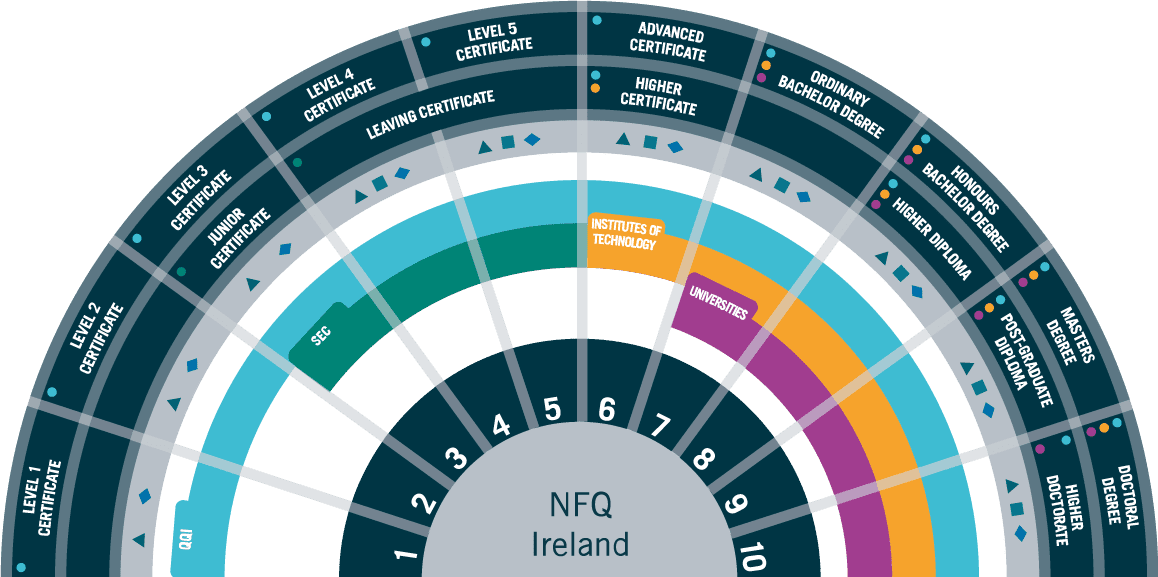

This course is suitable for those with a minimum qualification at NFQ Level 5 or a Leaving Certificate. Mature applicants and returners are also eligible. All applicants must have competency in spoken and written English.

Career Options

With the continued growth of the Pharmaceutical and Medical Device industry in Ireland, this course is suitable for those who wish to upskill to gain either

- An entry-level position within the Pharma/Medical Device Industries, or

- Supplement their existing core skills to pursue a similar role within the Pharma/Medical Device Industries (e.g. Finance, HR, IT etc.,)

Possible Pharmaceutical and Medical Device roles you could fill post completion of this course include:

- Support/Administrator

- Production Operator/Technician

- Maintenance Operator

- Quality Assurance

- Packaging Operator

- Warehouse Operator

- Product Builder

Apply Now

Our admissions team are on hand to assist you with your application and answer any questions you may have on the course.

Students who wish to apply to this course should follow the following application process.

Step 1: Enquire through the form at the top right of this page

Step 2: A member of our team will be in contact through phone or email

Step 3: If you are deemed to be eligible for the course, you will be sent an application form by email. You MUST fill in this application form and attach all necessary *documents (CV, ID, Transcripts, etc.)

Step 4: On submission of the completed application form and all documentation, your application will be sent to the associated department for final approval. You will receive an e-mail confirming your place on the programme. (Note: This process can take up to one week particularly during busy admission periods.)

*We accept scanned documents in a pdf format. Pictures of documents are not accepted.

**For those who are applying for Springboard funding, you will be directed to fill out an additional application form on the Springboard website, this is to confirm your eligibility to receive funding

Please note at any time if you have any questions please do not hesitate to contact us by email on admissions@innopharmalabs.com or call us (01) 485 334

Why up-skill for the pharmaceutical industry in Ireland?

- €3 billion in new capital investment

- €39 billion in exports

- Over 55,000 employed

- 9 of top 10 world’s biopharma companies in Ireland

- 12 of the top-selling drugs made in Ireland

- Over 8,000 new jobs predicted

Testimonials

The lectures all come from the industry so they know what the Pharmaceutical companies are looking for

Laura McCarthy, ERP Automation Admin at Pfizer Certificate in Pharmaceutical & Medical Device Operations Graduate

Our Blog

Blog

January 22, 2026

Rethinking “Human Error” in Biopharmaceutical Manufacturing

Author: Ann Ryan, PhD Researcher, Director of Industry Engagement & Training, Innopharma Education A recent publication from A...

Blog

April 3, 2025

AI in Biopharma: Transforming Manufacturing & Innovation

How AI, Machine Learning, and Automation are Transforming Biopharmaceutical Manufacturing Here at Innopharma, we are proud to show...

Blog

December 11, 2024

Looking for a Career in the Biopharmaceutical Industry? Everything You Need to Know

The biopharmaceutical industry is a rapidly growing sector that combines cutting-edge biotechnology with pharmaceutical science to...